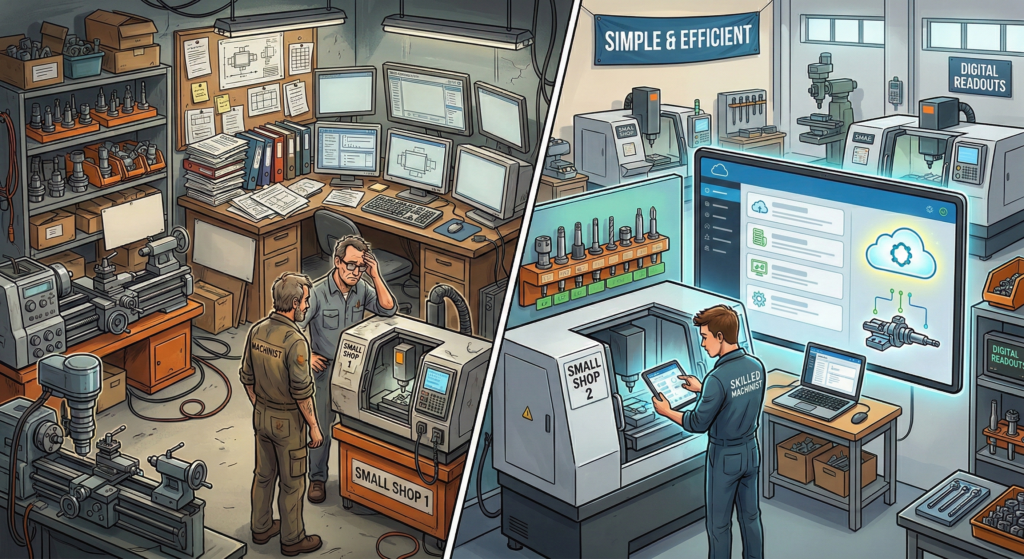

In any machine shop, the pressure is constant. Customers want high-quality parts, tight deadlines, and competitive pricing. In the daily rush to make chips and ship products, it's easy to fall into a cycle of "just get it done." A complex job comes in, the team scrambles, relies on memory, and solves the problem. Weeks later, a nearly identical job arrives, and the same scramble begins all over again. Sound familiar?

This cycle of reinventing the wheel is not only inefficient but also costly. The antidote is a disciplined approach to a task many overlook: meticulously tracking your work. This isn't just about paperwork; it's about building a library of knowledge that drives quality, streamlines preparation, and future-proofs your operations.