The Imperative for Digitization

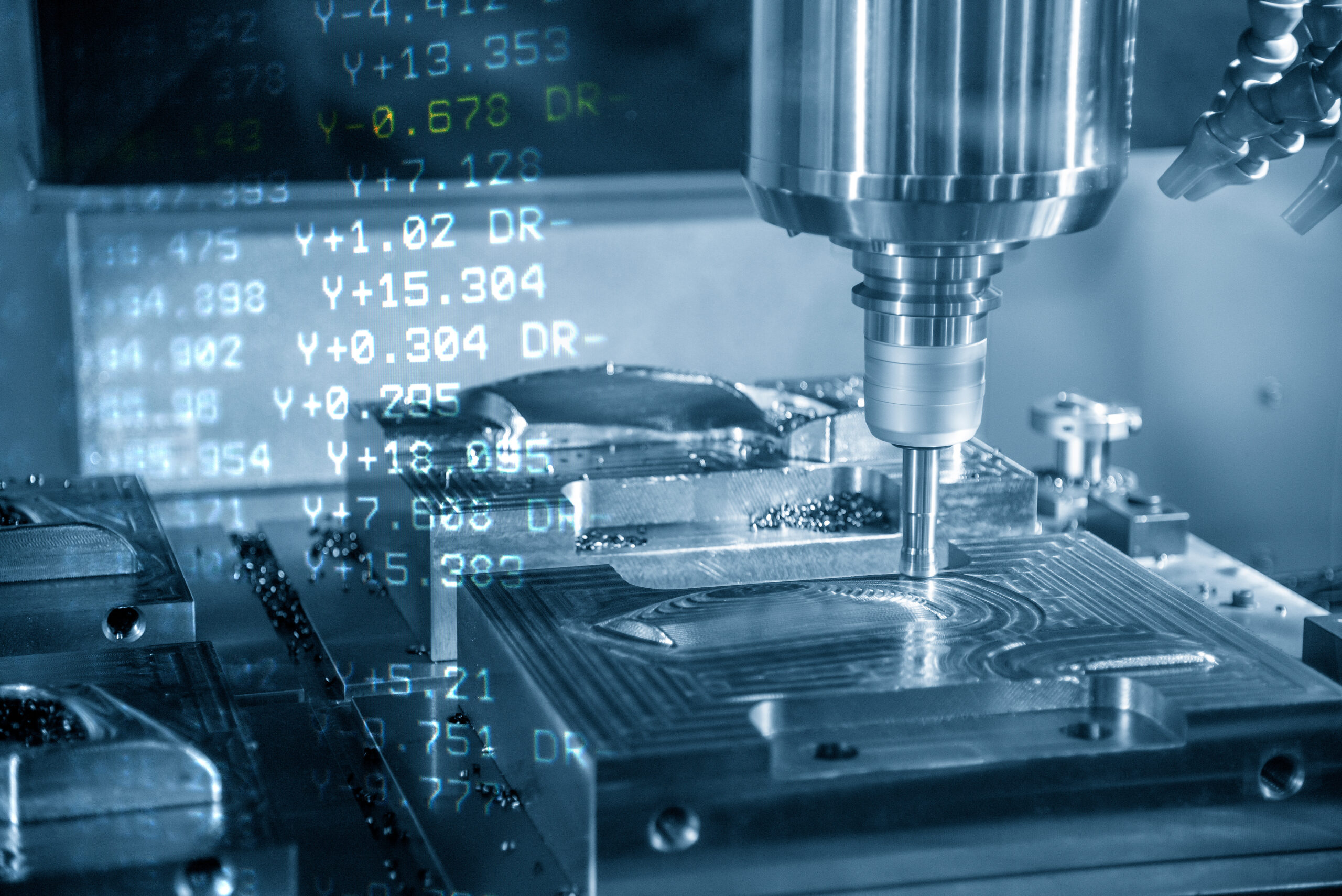

The primary driving force behind the push for digitization in machine shops is the ubiquity of electronic data. Today’s manufacturing environment demands real-time access to vast amounts of information, including design specifications, tool data, and machining parameters. Traditional methods of handling this information, such as paper blueprints and manual data entry, are no longer sufficient. Here’s why:

- Efficiency and Productivity: Digital systems streamline workflows, reducing the time spent on manual data entry and minimizing errors. Automated data transfer ensures that the right information is always available, leading to quicker setup times and faster production cycles.

- Accuracy and Precision: Electronic data eliminates the discrepancies that often arise from manual processes. Digital tools provide precise, consistent information, ensuring that every part is machined to exact specifications.

- Data Integration and Accessibility: In a digitized environment, data from various sources can be easily integrated and accessed. This holistic view of operations enhances decision-making and allows for better resource management.

- Scalability and Flexibility: Digital systems can scale with the business. Whether a machine shop is expanding its operations or adapting to new technologies, a digitized process can accommodate growth and change more effectively than traditional methods.

- The Power of the Cloud: Cloud-based solutions offer a secure platform to store and access your data from anywhere. This eliminates the need for physical servers and empowers collaboration across teams and locations.

The Role of MachiningCloud

MachiningCloud is at the forefront of the digital transformation in machining and can be your partner in this digital transformation. It offers features and resources that help machine shops harness the power of electronic data to optimize their processes. Here’s how MachiningCloud can facilitate this transition:

- Comprehensive Tool Data: MachiningCloud provides access to an extensive database of cutting tool information. Users can easily find and download detailed specifications, 3D models, and application data for a wide range of tools. This ensures that the right tool data is always at hand, reducing setup times and improving machining accuracy.

- Seamless Integration: The platform integrates seamlessly with machining systems such as CNC machines and CAM software, allowing for smooth data transfer and process automation. This connectivity ensures that the latest tool data and machining parameters are directly available to the integrated systems, reducing the risk of errors and enhancing operational efficiency.

- Cloud-Based Accessibility: As a cloud-based platform, MachiningCloud provides access to data from anywhere, at any time. This flexibility is crucial for machine shops that operate multiple shifts or have geographically dispersed operations.

- Enhanced Collaboration: MachiningCloud fosters collaboration between different departments and teams within a machine shop. Engineers, machinists, and operators can all access the same up-to-date information, ensuring that everyone is on the same page and working towards the same goals.

- Up-to-Date Information: Tool manufacturers frequently update their data to reflect the latest advancements and innovations. MachiningCloud ensures that machine shops always have access to the most current information, helping them stay competitive and at the cutting edge of technology.

- Centralize Data: Store all your design files, work instructions, and production information in a single, secure location.

The digitization of processes in machine shops is not merely an option but a critical step towards future-proofing operations. The shift from traditional methods to electronic data management enhances efficiency, accuracy, and scalability. The rapid advancement of technology has made data more accessible electronically, while traditional forms of data storage and transfer are becoming obsolete.

For machine shops, digitizing processes is not just a trend but a necessity. Embracing digital transformation can significantly enhance efficiency, accuracy, and competitiveness. MachiningCloud stands out as a powerful ally in this transformation, offering the tools and resources needed to navigate and thrive in a digital landscape. By adopting digital solutions like MachiningCloud, machine shops can ensure they remain competitive, efficient, and ready to meet the challenges of the modern manufacturing world